Can LED Lighting Benefit Chemical Treatment Plants?

By Leah • Nov 07, 2018

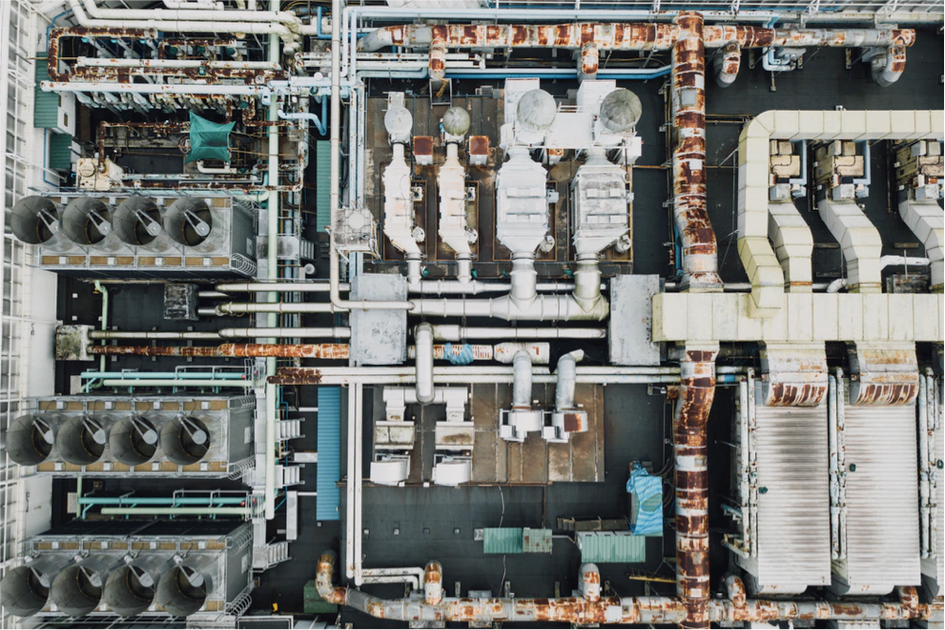

There are many considerations operators of chemical treatment plants need to make. Safety is not the least of them, but all the disparate elements need to come together for effective production and maintenance. While careful regulations and protocol have been instated for as long as feasible, this doesn't mean new innovations can't be included. Might such innovations include the benefits of LED lighting?

General Benefits of LED Lighting

Before we look into how LED lighting might specifically benefit the chemical treatment industry, we should look into some of the reasons companies are updating to LED lighting across all commercial usage.

Firstly, LED lighting is much more energy efficient than its high intensity discharge forebears. HIDs such as high pressure sodium or metal halide lamps have great light quality, but it comes at a price. The amount of energy needed to create the arc between electrodes is so high, it needs to be controlled by a ballast lest it send so much energy the bulb shorts. This energy continues to surge between electrodes until the bulb reaches its desired intensity.

As an HID such as a metal halide combusts both the gas contained within the glass and the metal and halogen compounds which give them their name, a lot of the electrical energy does not come out as light, but as waste heat. LED lighting does not have the same problem and uses very little energy in a much more efficient manner.

Such efficiency results in greater cost effectiveness. Less energy put into a bulb means smaller numbers appearing on an invoice. With greater production continually lowering initial costs and plug and play bulbs meaning less for installation fees, the longer you delay upgrading, the more money you waste.

Less Heat Has Other Benefits

Chemical treatment plants are supremely controlled environments. The ambient temperature required to carry out chemical treatment needs to be exact, otherwise it can affect the process and even react badly with the chemicals. Maintaining this temperature is easier with LED lights. The lack of wasted heat means you can control ambient temperature more easily and a constant rate of energy usage means you don't have to readjust.

LED Lighting Fixtures Are Robust

While heat is a concern, it is not the only one in chemical treatment plants. Noxious gases and hazardous pollutants are a real concern. With HIDs, florescent lamps and other types of lighting systems, the casings and fixtures need to be specially reinforced. This costs money and isn't always effective. It can also negatively affect the quality of the light.

Part of the specific problem (whether it be for water treatment or other chemical treatment processes) is that any of the chemicals react with their environment. For corrosive or high humidity environments, light fixtures with metal parts might not withstand the pollutants. LED lighting encases their elements in non-metallic fixtures which won't react like other bulbs. It will do this without affecting the quality of light output.

With LED lighting, the fixtures are designed to work in the most extreme conditions. They do not require the bulbous space needed for HIDs and the fixtures themselves are compact. Many fixtures are naturally water resistant and it is much easier to make them waterproof. This is in part due to not needing to release the heat HIDs produce. All this and the light which emanates can be tailored to the specific needs of the plant.

Chemical treatment plants need an environment which is carefully controlled. With progammability, temperature control, robustness and quality, LED lighting means keeping the delicate balance of these industrial spaces is made easier. This is not to mention the savings and energy conservation which goes hand in hand.